Environment

Efforts toward a Circular Economy

Our Group has set "RealizeRealize a Circular Economy" as a materiality (priority key challenge). We are working on this as one of the specific approaches to Our Mission, "creating social value through maximizing the potential of assets."

Major initiatives

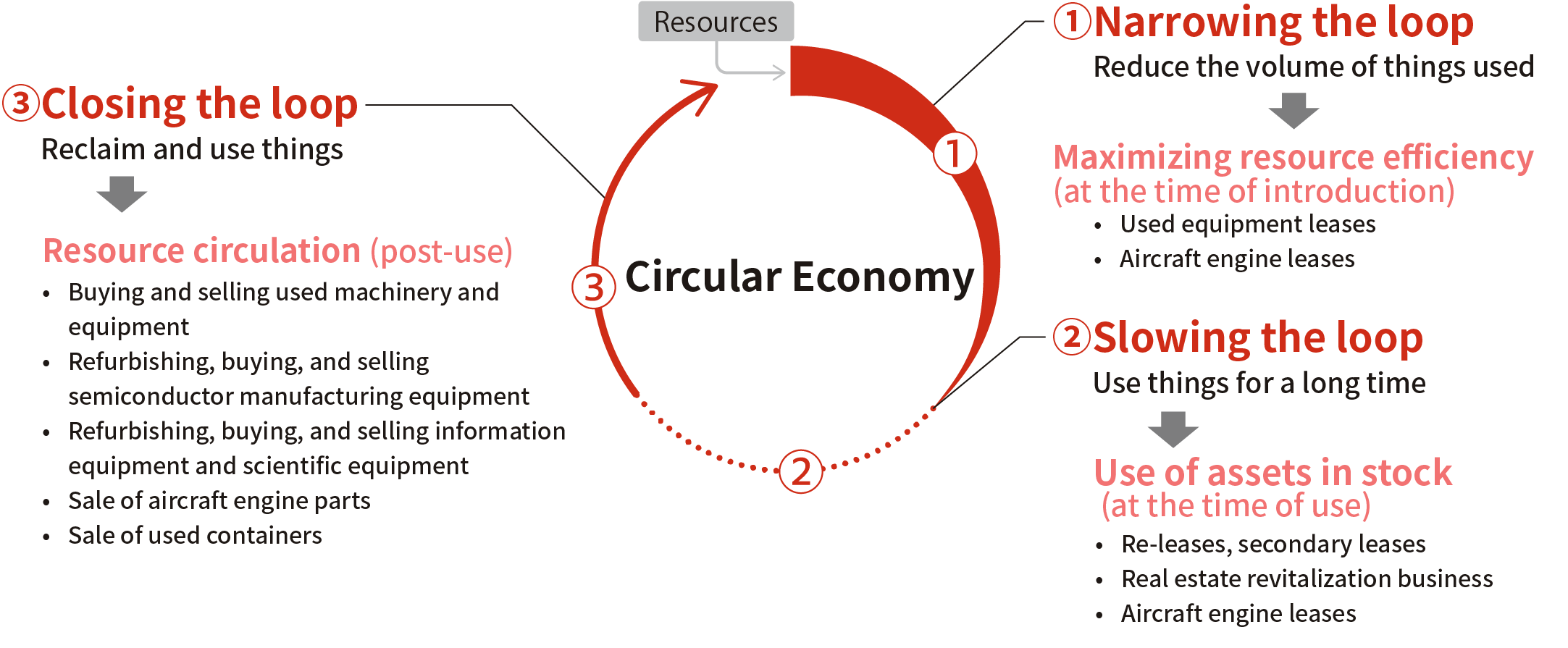

Our Group contributes to the realization of a circular economy through a variety of businesses.

Due to the nature of its business model, leasing, which is our founding business, has a high affinity with a circular economy, and our Group has a variety of value propositions and solutions that maximize the value of the facilities and equipment covered by our contracts. As shown in the chart below, our Group’s circular economy-related businesses are linked to various factors for realizing a circular economy. We are working on businesses related to a circular economy in many areas, such as those shown on this page.

References: Tasaki, Tomohiro (2024). Transformation and information dissemination towards the realization of a circular economy. Ad Studies, Vol.87, 2024.

Bocken, N. M. P., de Pauw, I., Bakker, C., van Der Grinten, B (2016). Product design and business model strategies for a circular economy. Journal of Industrial and Production Engineering, 33(5): 308–320

Value and solutions provided by our Group at the lifecycle stages of assets

① Time of introduction: maximizing resource efficiency—narrowing the loop

Providing a wide range of finance functions

We provide the appropriate things that meet customers needs, such as equipment that promotes decarbonization and energy conservation and engines that contribute to improving the utilization rate of aircraft. We also provide a wide range of financing functions such as operating leases, sharing, and rentals to fulfill customers needs for use (as opposed to ownership).

- Related businesses

- Used equipment leasing, aircraft engine leasing, ESG lease promotion business, GX Assessment Lease, etc.

② Time of use: use of assets in stock—slowing the loop

Lease contracts

In a lease contract, when the lease contract period expires, we provide two options: “re-lease contract” (usually a oneyear extension contract) and “return.” If “re-lease contract” is chosen, the initial contract period will be extended. This allows for extended use every year at a lower cost than the initial contract period. In addition, residual value-setting leases support the restructuring of leases (secondary leases) based on residual value.

Real estate revitalization investment business

In an effort to encourage the use of assets in stock, we conduct business in which we acquire old offices and other facilities and revitalize their real estate value by updating their equipment and renovating their common areas.

Aircraft engine lease business

We maintain and improve the asset value of engines through timely and appropriate maintenance, making it possible to use them for long periods of time.

- Related businesses

- Equipment refurbishing, real estate revitalization business, aircraft engine leasing, etc.

③ Post-use: resource circulation—closing the loop

Secondary use

If “return” is selected when the lease contract expires, the returned property will be used for secondary use by new customers. Leveraging our Group’s strengths such as our expertise and network, we work in multiple areas, purchasing not only equipment returned by customers, but also idle assets and equipment of customers, leasing them to other customers, and engaging in the refurbishing and reuse business.

Sale of aircraft engine parts

We are also pursuing the possibility of reusing and recycling aircraft engines and information equipment, which are difficult to reuse, by dismantling and maintaining them and engaging in a business to sell reusable parts as spare parts. Ultimately, we contribute to the realization of a circular economy by properly disposing of items that are difficult to reuse and recycle.

Results Related to Resource Circulation (post-use)

| Items | Description | FY2024 |

|---|---|---|

| Sales Value of Used Machinery and Equipment | Total sales amount of used machinery and equipment for industrial machine tools, semiconductor manufacturing equipment, scientific equipment, construction equipment, medical equipment, and information equipment for the Customer Solutions Unit | ¥16.3 billion |

| PCs Refurbished and Sold | Engaged in reuse business to purchase properties returned at lease expiration and customers’ idle assets, and conduct appropriate refurbishing, including data erasure | Over 480,000 units |

Target related to the resource circulation for plastics

The MHC Group has set a target to reduce plastic waste generated from operating assets such as leased assets in response to the Act on Promotion of Resource Circulation for Plastics.

<Target>

Effective utilization *1 of plastic waste *2 generated from operating assets, such as leased assets, by fiscal 2030 : 100%

- Target companies: Group companies with large amounts of waste (Mitsubishi HC Capital Inc. and MHC Eco Solutions Co., Ltd., which generate more than 250 tons of plastic waste)

- The percentage of the plastic waste processed through material, chemical, or thermal recycling

Percentage of plastic waste generated from operating assets such as leased assets processed through material, chemical, or thermal recycling

| Target companies | FY2022 | FY2023 | FY2024 |

|---|---|---|---|

| Mitsubishi HC Capital | 92.1% | 95.2% | 94.2% |

| MHC Eco Solutions | 95.7% | 97.1% | 90.9% |

Stakeholder engagement

MHC closed a capital and business alliance agreement with ZERO CO., Ltd. (hereinafter “ZERO”), and is working to reduce food loss and CO 2 emissions in Japan by providing sales support, financing for installation, and operational support for unmanned vending machines known as Food Loss Reduction Box ZERO provided by ZERO.

MHC, as a service user, introduced and installed the vending machine s at its Marunouchi Office, Nishi Shimbashi Offi ce, Nagoya Office, and Osaka Office, enabling i ts employees to buy foods that are safe to eat but cannot be distributed due to their short shelf life, seasonal packaging, damaged packaging, etc.

Amount of GHG reduced through Box ZERO installed in the Company (September 2024 to March 2025)

| FY2024 | Locations | |

|---|---|---|

| Amount of GHG reduced | 2,672kg-CO2e | Marunouchi Office, Nishi-Shimbashi Office, Nagoya Office, Osaka Office |

- Measuring tool: My-Eco-Ruler

- Conditions for calculating the amount of reduction (key conditions): An intake of 1 kcal is set as the functional unit and global warming is set as the impact category. The latest GWP100 values in the IPCC’s Climate Change 2021 (Sixth Assessment Report) is used. To represent average food consumption in Japan, the amount of activity by ingredient (amount of consumption and calories) is calculated based on public statistical information, such as the Food Supply and Demand Table published by the Ministry of Agriculture, Forestry and Fisheries. Emission factors for respective activities are calculated based on databases such as IDEv3.1, 3.3, Ecoinvent v3.10.

The amount of reduction is calculated based on data provided by ZERO, under the assumption that the reduction of food through the use of ZERO BOX leads to the reduction of activities throughout the entire product life cycles-from production and processing to consumption and disposal—of foods with equivalent calorific value.